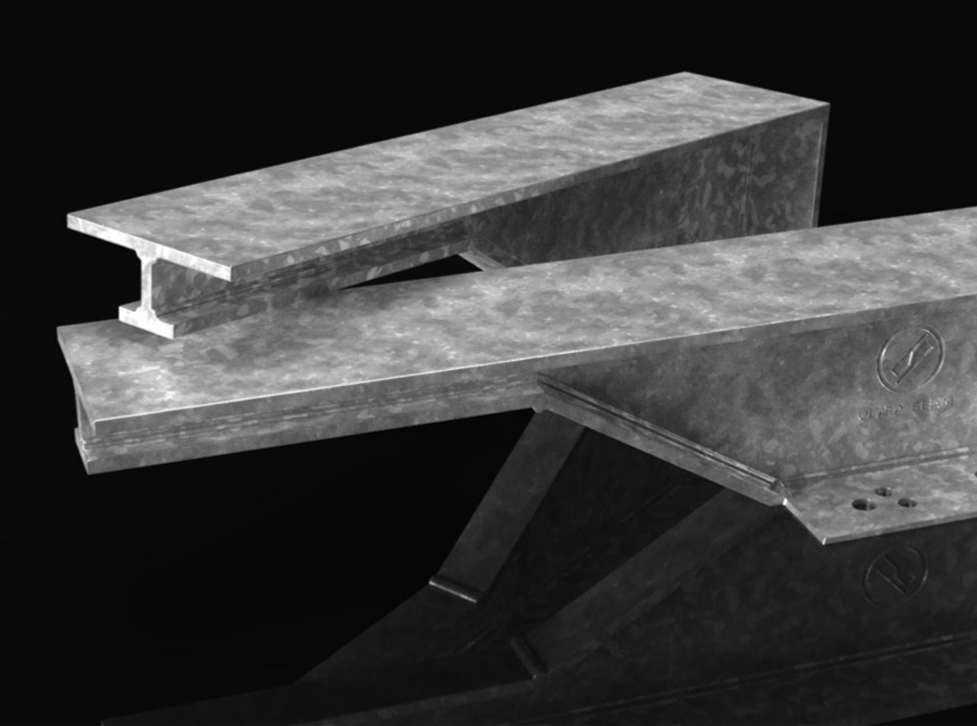

The Strength of Ultra-Beam was our main priority in its concept and design. Our target strength of 3500kg was paramount in our design process in many variations of the original format were produced until finally Ultra-Beam was born. It was now time to put it through testing to make sure it could perform.

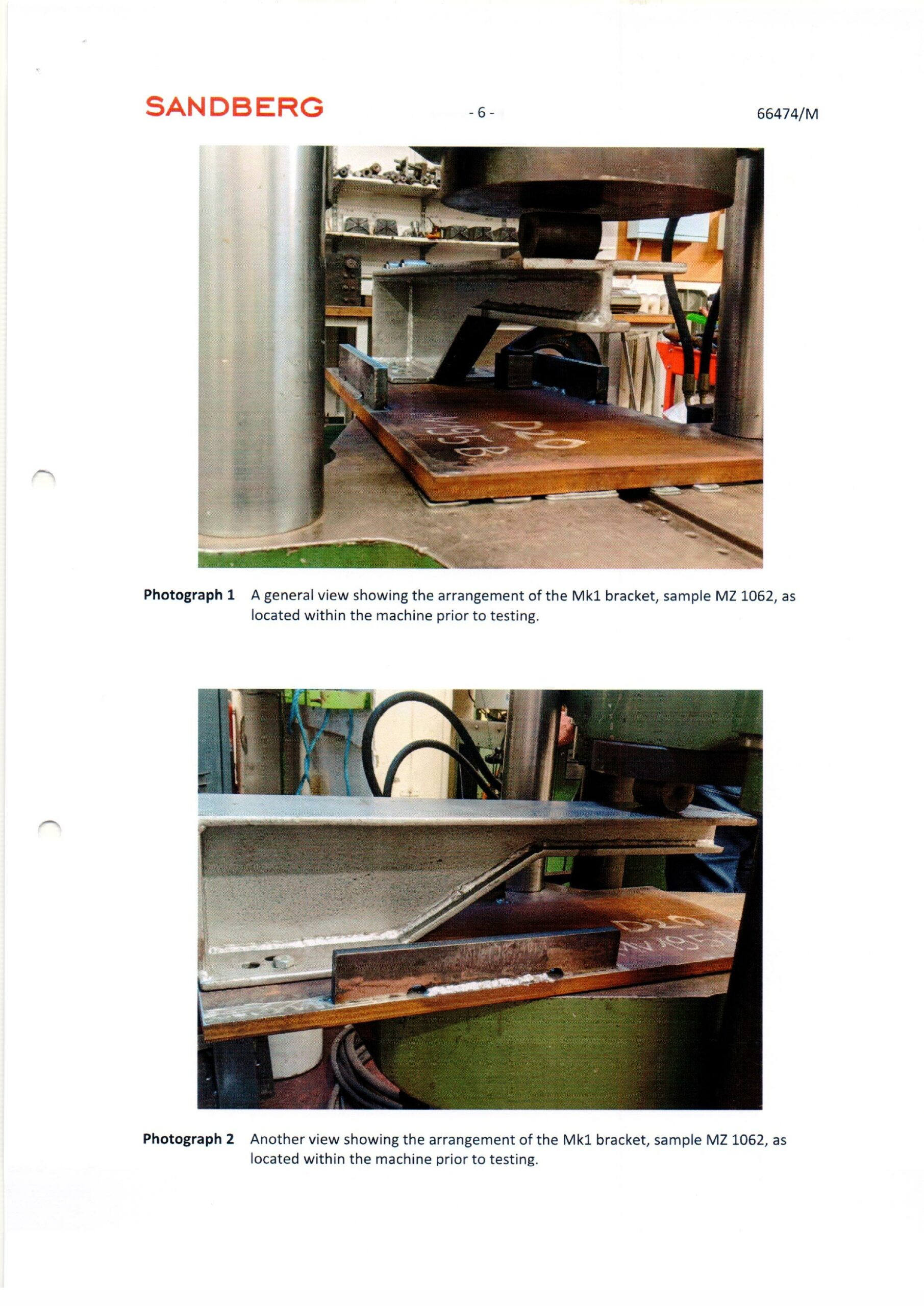

Testing

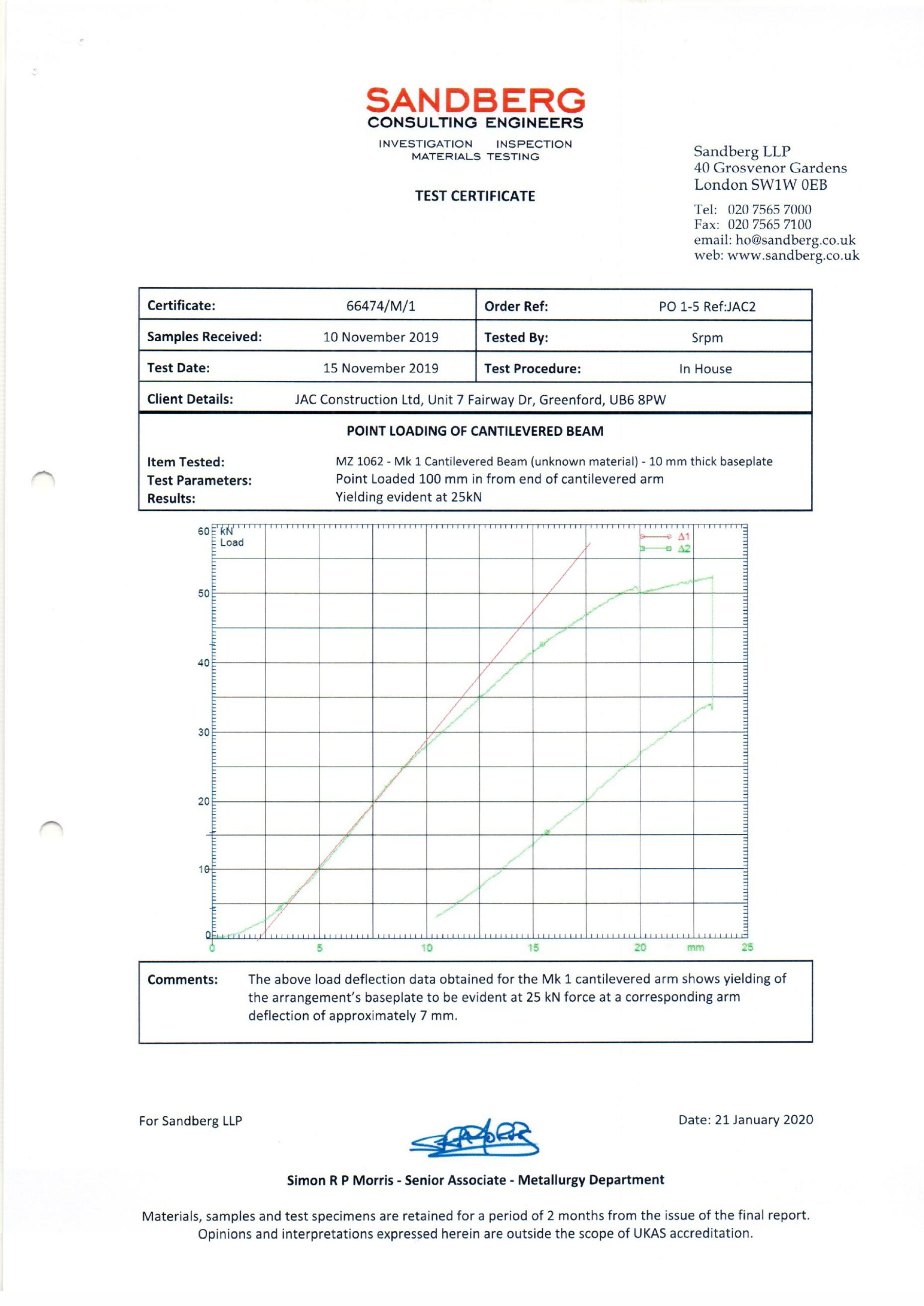

Mark 1 Ultra-Beam that was put through testing at Sandberg failed with an applied testing load of 25kN on the base plate. The cantilevered arm also showed evidence of bending at higher loads.

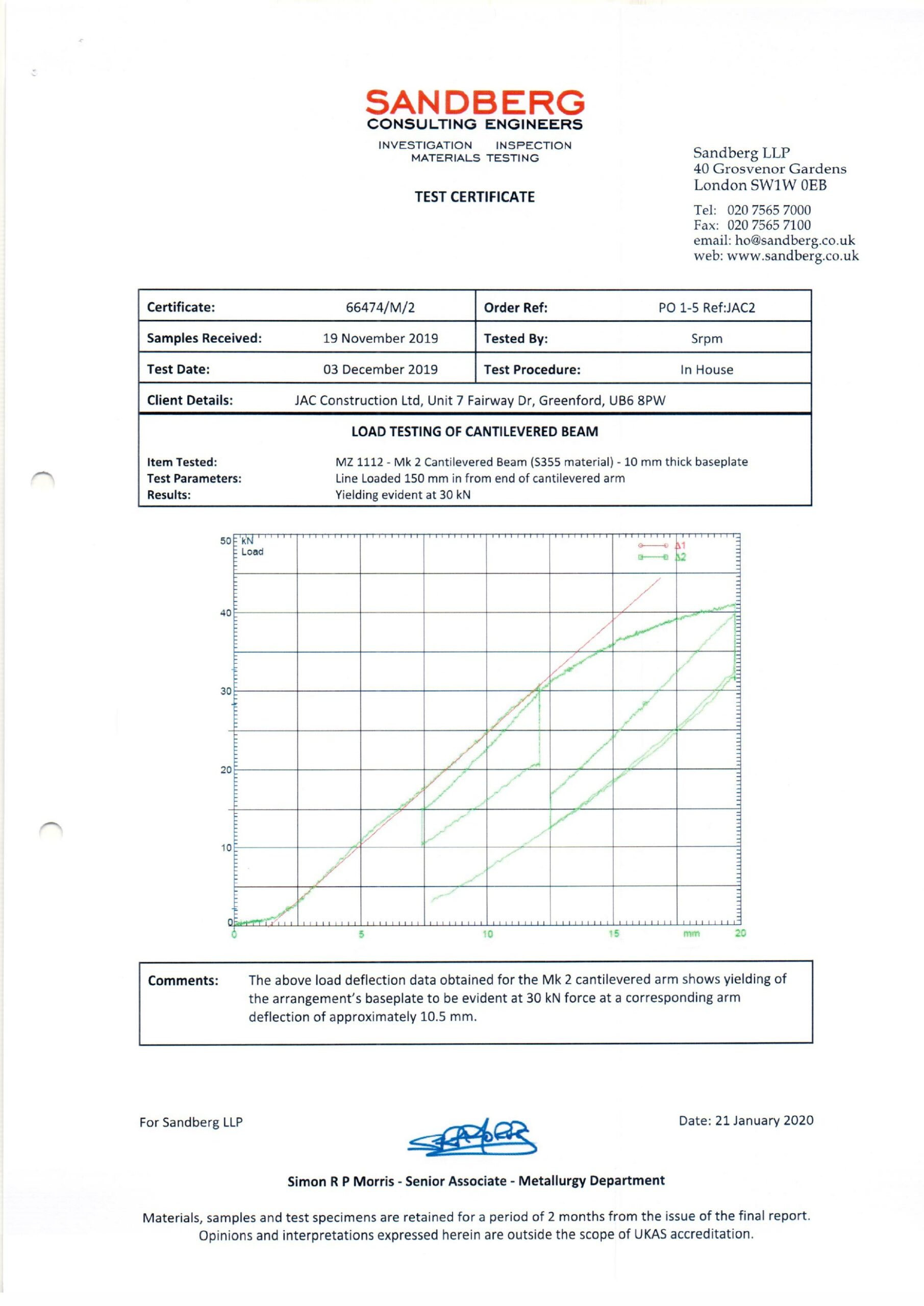

We increased the thickness of the base plate and Mark 2 was then put through into testing. With an applied testing load of 30kN the base plate failed and cantilevered arm also showed evidence of bending.

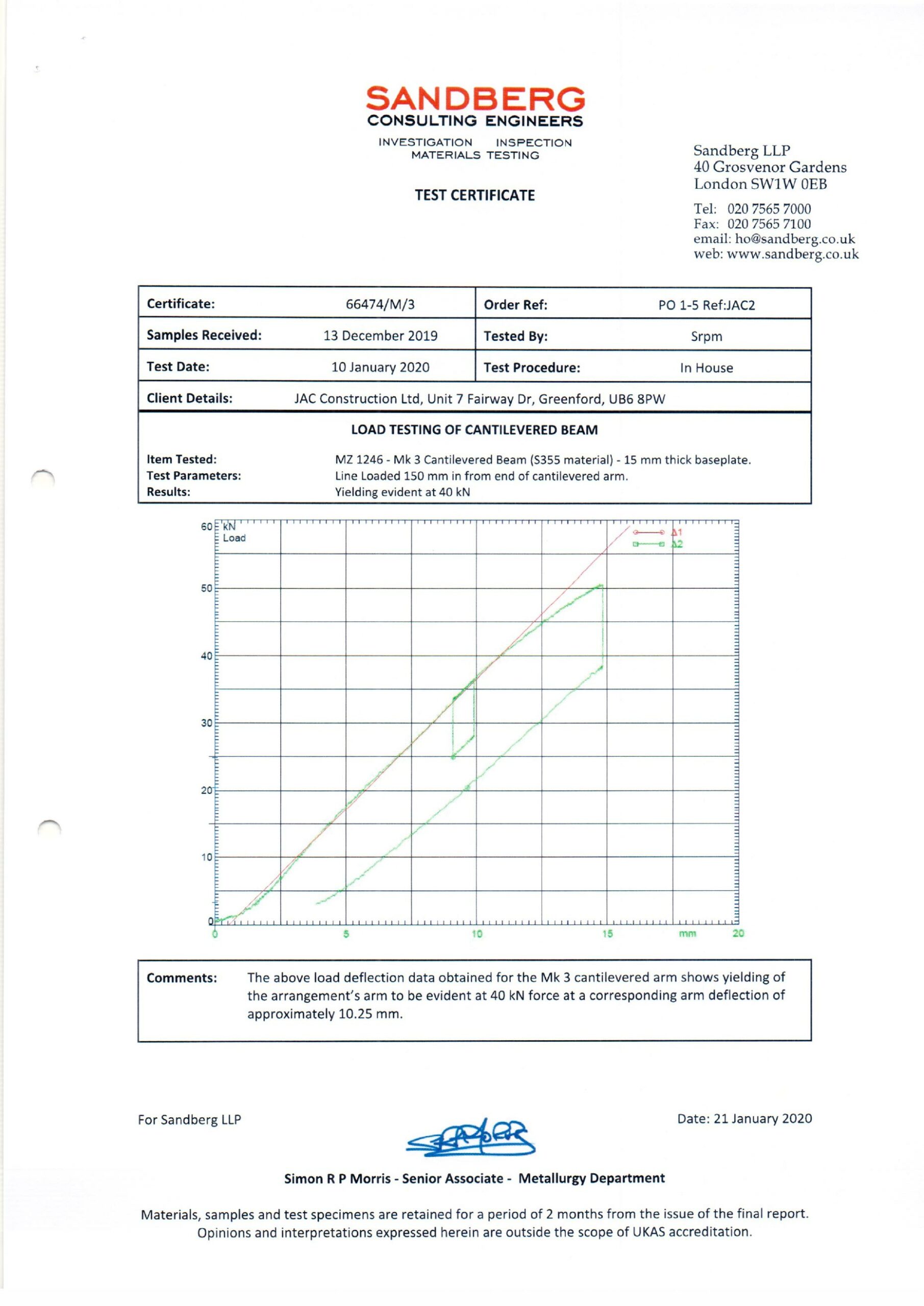

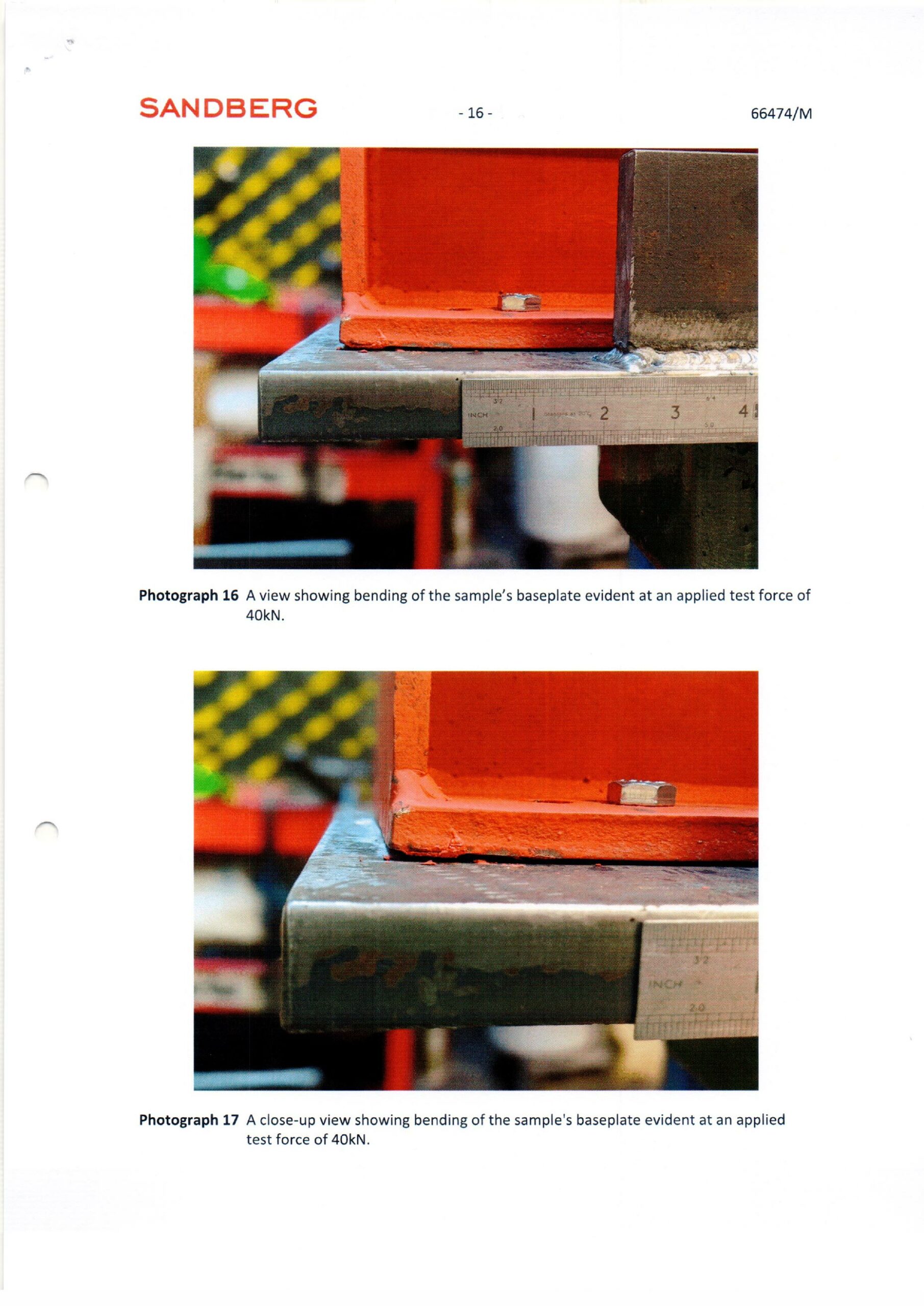

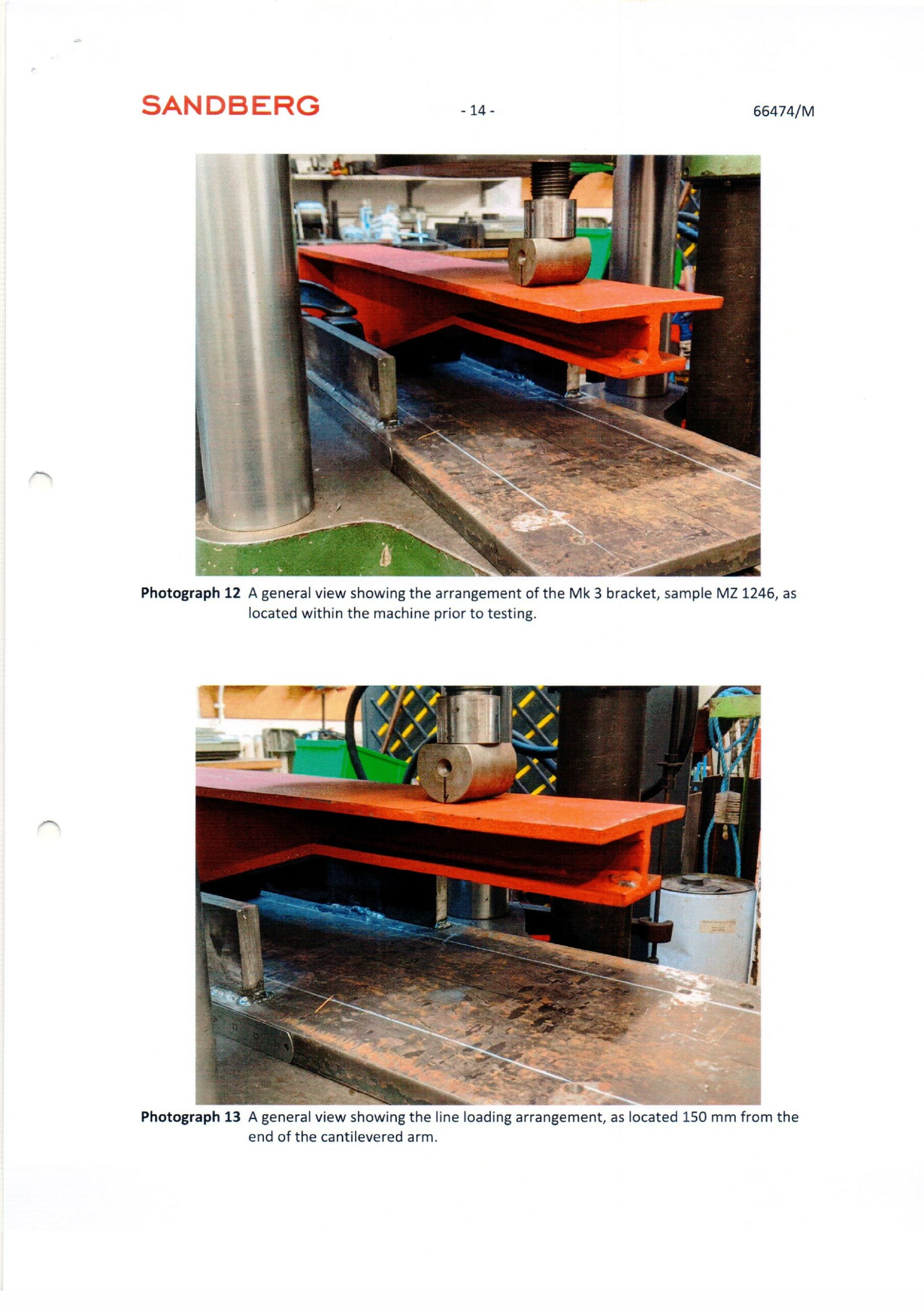

On the final Mark 3 version we increased the base plate to 15mm and used a high grade S355 steel with an applied exceeding 40kN the Ultra-Beam 350 was born.

“Testing A Product Is A Learning Process ”