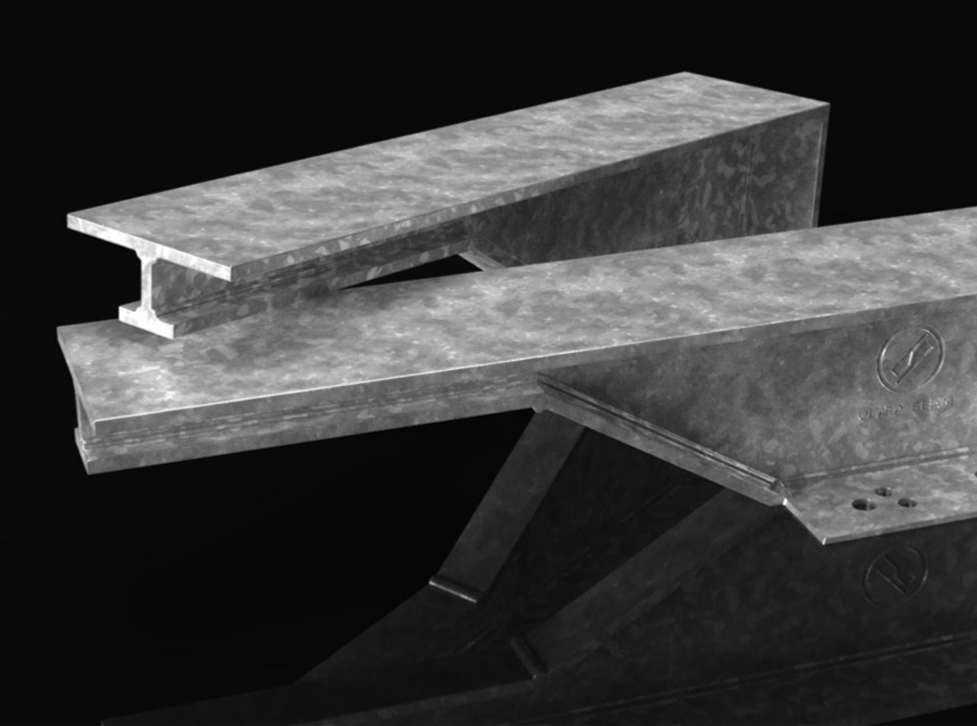

Admittedly, the roof could have been stripped and reinstated and supported with conventional needling and propping. We were able to avoid this and the additional cost with UltraBeam350.

The existing structure was being held up by a pair of beams with a column in the middle. The job was to make the opening 2 meters wider and remove the column, a large 533 x 210 x 82kg was to be used to replace the existing steel.

Unique solution to protect the roof and rooflights

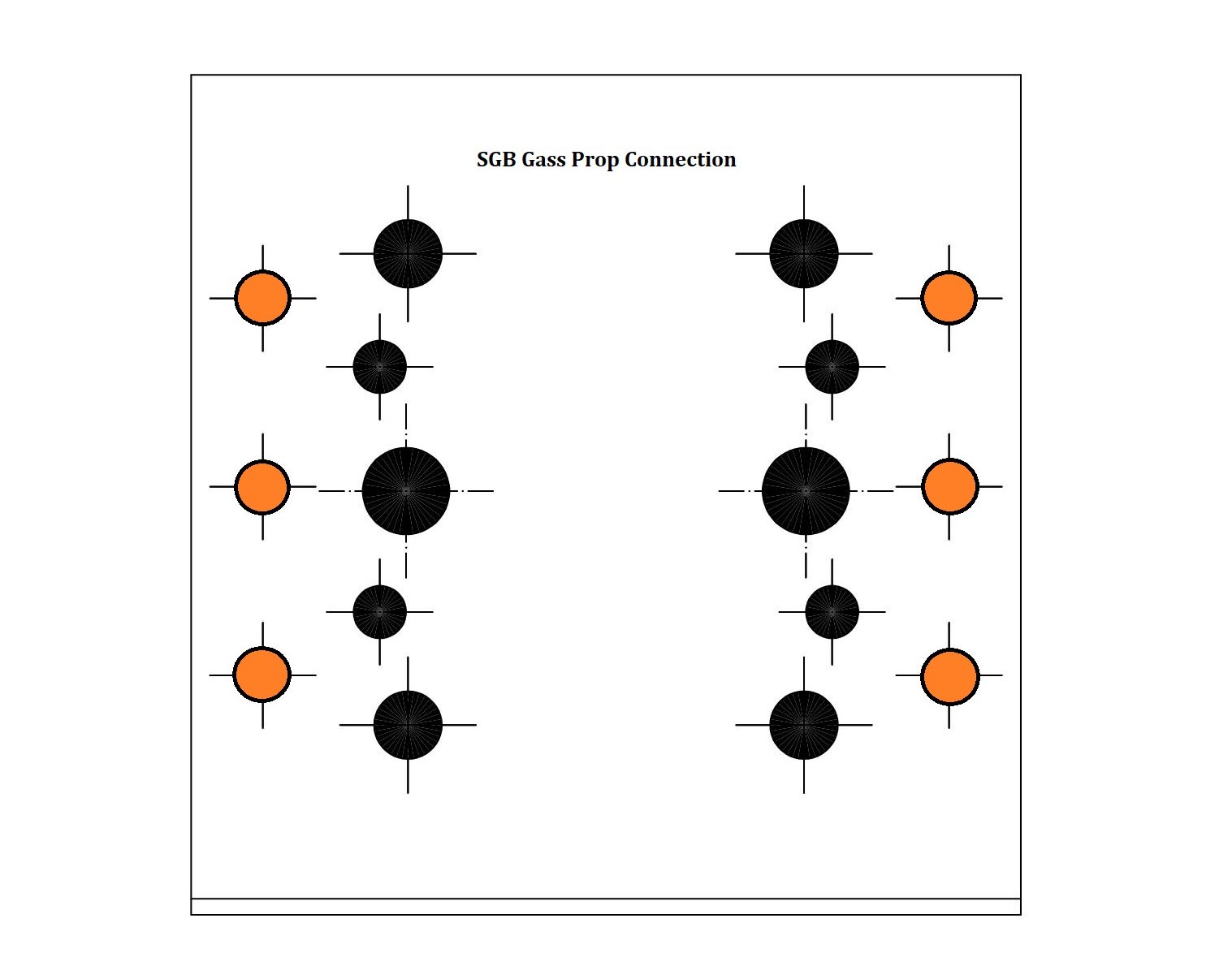

Our temporary works consisted of UltraBeam on Gas props on the inside of the existing wall with Acrow props supporting the underside of the roof. Using UltraBeam to support the main rear elevation wall we were able to install the new beam to the underside of the existing pitched roof with no damage to the roof what so ever.

The temporary works engineer had no problems making the line loads work with UltraBeam 350.

“The contractor saved time and the client saved money. That is a win win for UltraBeam 350. ”