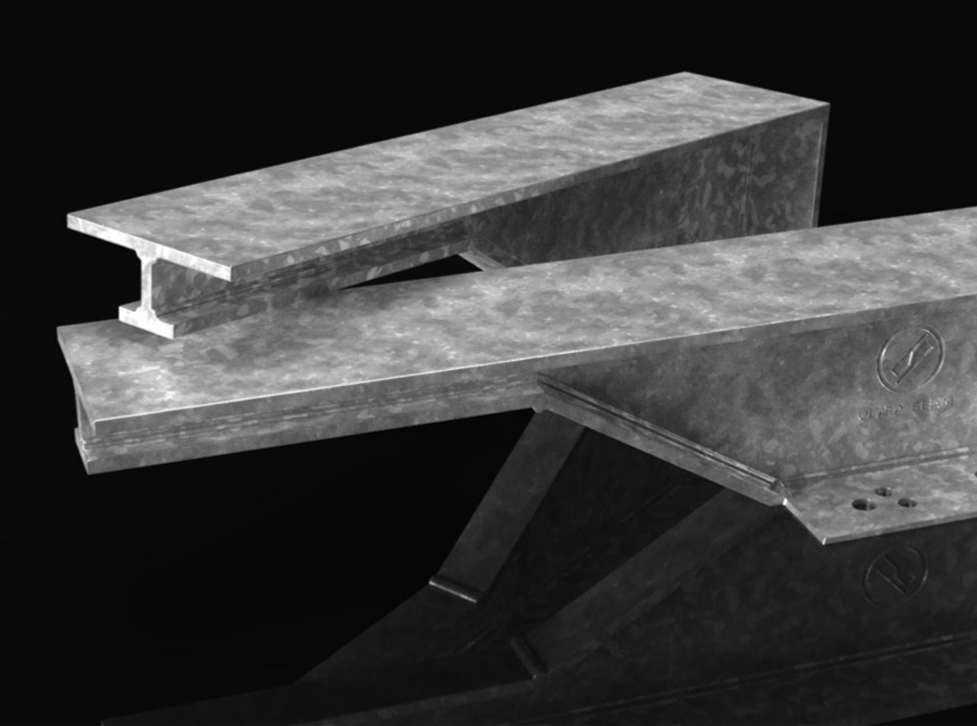

We started by using high-grade S355 steel fabricated in our CE approved workshop. With the help of our structural engineers, over the next few months and a couple of prototypes later, the final concept and design started to take shape.

Rigorously Tested

Our unique patent-pending small beam section that has run through all of our designs has been the main component that produces the strength of the support blade, that we were looking for. When we completed the final test design, we chose Sandberg LLP, who are world renowned specialists in material testing and consultancy, to put Ultra-beam through its paces.

It is due to this innovative design of the Ultra-beam support blade that the overall bearing load of 3500kg was reached. After rigorous testing and a few upgrades, we finally achieved our goal of a factored load of 3500kg. We then carried out extensive on-site testing, well documented in our case studies, where we put Ultra-beam though its paces. With this achieved, we are now confident that Ultra-beam can be used in temporary works design.

“It is due to this innovative design of the Ultra-beam support blade that the overall bearing load of 3500kg was reached ”